DRYIT Semi-Continuous Tray Drier

Practical Action

Construction

1) Cut each part from 25 x 25 mild steel angle. The cutaways in the centre beams are for the

rods connected to the lifting fingers.

2) Weld the two back legs (4) and the back top and bottom beams (2, 8) to form a flat,

square rectangle with mitre joints at each corner. Weld the two front legs (4) to the front top

beam to from a square, flat goal post arrangement with two mitre joints.

3) Parts 3, 5 and 7 are butt jointed to the rectangle and goal posts. Butt joints are used fr

flush fitting cladding.

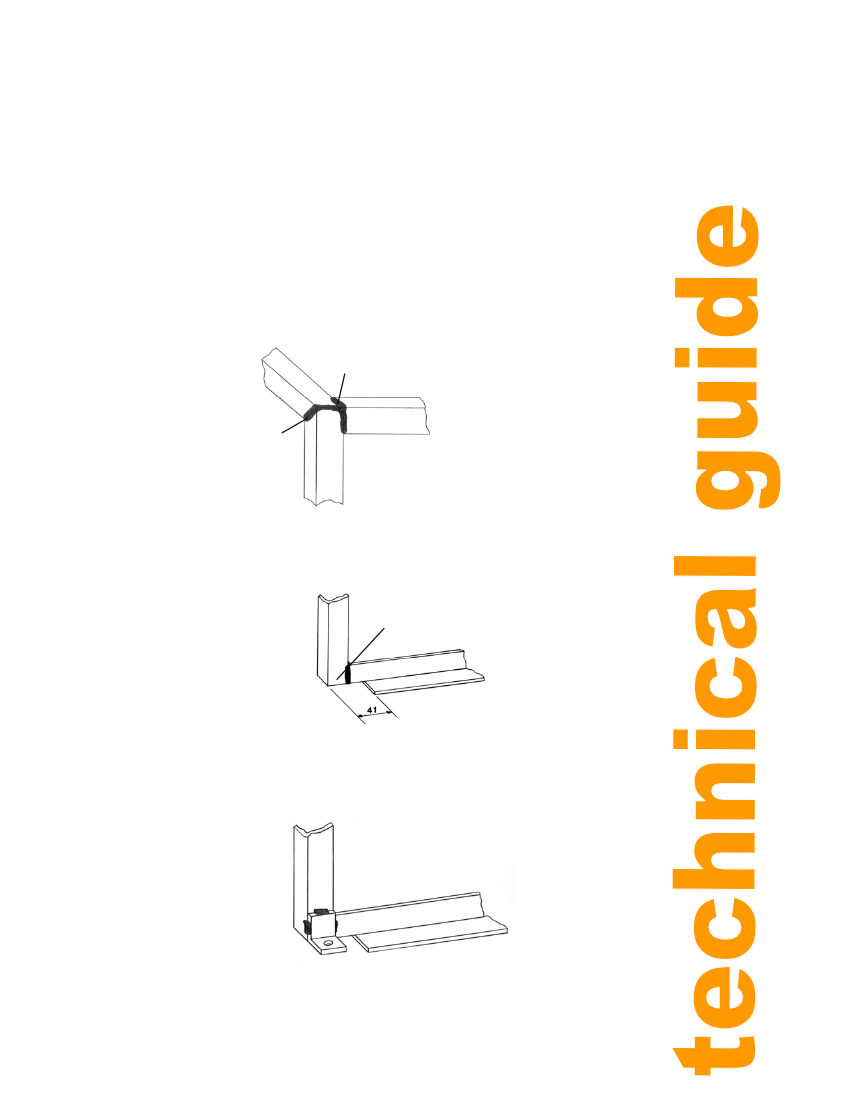

A detail of the mitre and butt joints are shown in figure 7

Butt

Mitre

Figure 7: Mitre and butt joints

4) Weld the lower beams (7) tot the bottom of the legs as shown in figure 8

Butt

Figure 8: lower beam-ends are flush

5) Drill the angle pads then weld them in position, flush with the bottom of legs, as shown in

figure

Figure 9: Angle pads

6) Mark and drill the upper pads then weld to the frame, in the position shown in TD003

11